To pass on skills, it is necessary to consider the elements that define the technique and record them by measuring them. In 2019, we decided to consider and implement a plan to pass on skills by encouraging people to reproduce the technique while using the measured values as a guide. We will consider what is important for each task to be passed on. When considering the recording of manual skills, the recording targets for work posture include the position of the feet, the flexion of the feet, the position and angle of the waist, the direction of the head, the direction of the eyes, the shape of the arms, and the position of the hands. First, we will narrow down the recording targets and focus on the fingertips of the arms and hands. The positional relationship of each part of the body can already be grasped by motion capture technology for posture. We have already developed a function to identify the degree of finger spread and the position of the fingers by image processing of a dedicated finger recognition camera. Therefore, it was possible to detect the direction applied to the fingertips from the position and shape of the fingers. All that is left is a device that directly measures the force applied to the fingertips.

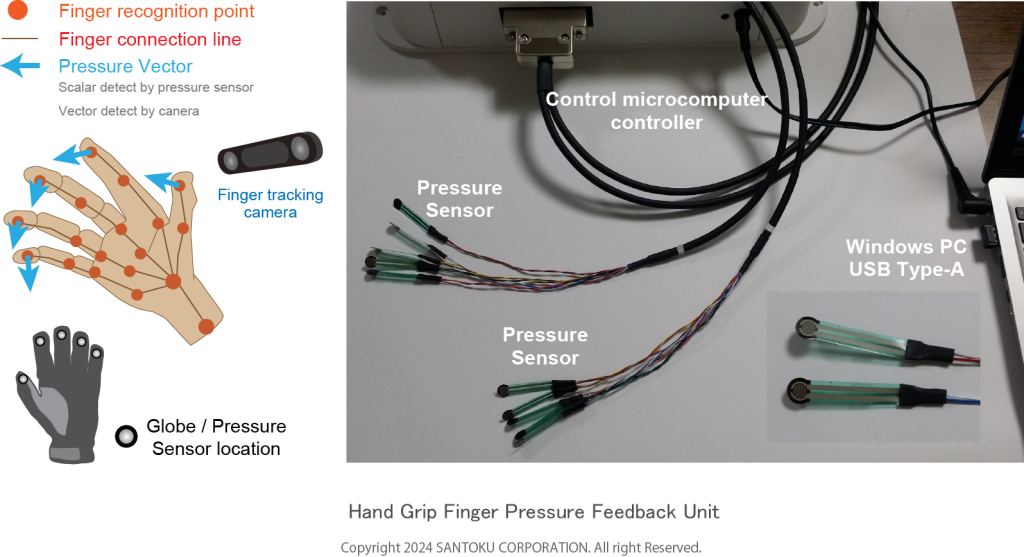

In order to detect the pressure applied to the fingertips, we developed a glove with a film-type membrane force sensing resistance type pressure sensor attached to the fingertip pad. In order to measure the pressure of each finger on both hands in real time, we designed a control system that measures a total of 10 pressures. The figure shows the pressure sensor and the control unit equipped with a microcomputer. The pressure that can be measured is 0.2N-20N. We also developed a weight calibration to improve the accuracy of the pressure measurement, but the measurement variation of the sensor itself is ±2%. The sensitivity characteristic of the sensor to weight changes is <3msec. The measurement interval of the control system is determined by the performance of the CPU and A/D converter. The pressure vector applied to the finger is provisionally defined as occurring in the vertical direction from the finger pad, and the software is built, but the measurement accuracy is determined by the measurement accuracy of the motion tracking. Although the development of the elemental technology of the function was once completed, it was not put into practical use because the project to transfer the manual assembly of machine parts, which was intended to use this technology, was canceled.