The pain reproduced by RiMM’s tactile reproduction gloves is a pain reproduction using electrical discharge to the skin. Since many workplace accidents are painful, such as cuts, entrapment, pinching, and burns, we are trying to reproduce a different type of pain without electrical stimulation. In order to reproduce pain in a way other than discharge, we focus on the use of the thermal grill illusion. The thermal grill illusion is an illusion phenomenon in which pain is felt by continuously applying alternating hot and cold sensations to the skin. The advantage of this method is that it uses a temperature that does not damage the skin and applies hot and cold sensations to the skin alternately, making it feel itchy and painful. In addition, we have started developing a unit based on the assumption that the thermal grill illusion may be able to generate a burning pain, and we have determined that it is effective for reproducing burn accidents.

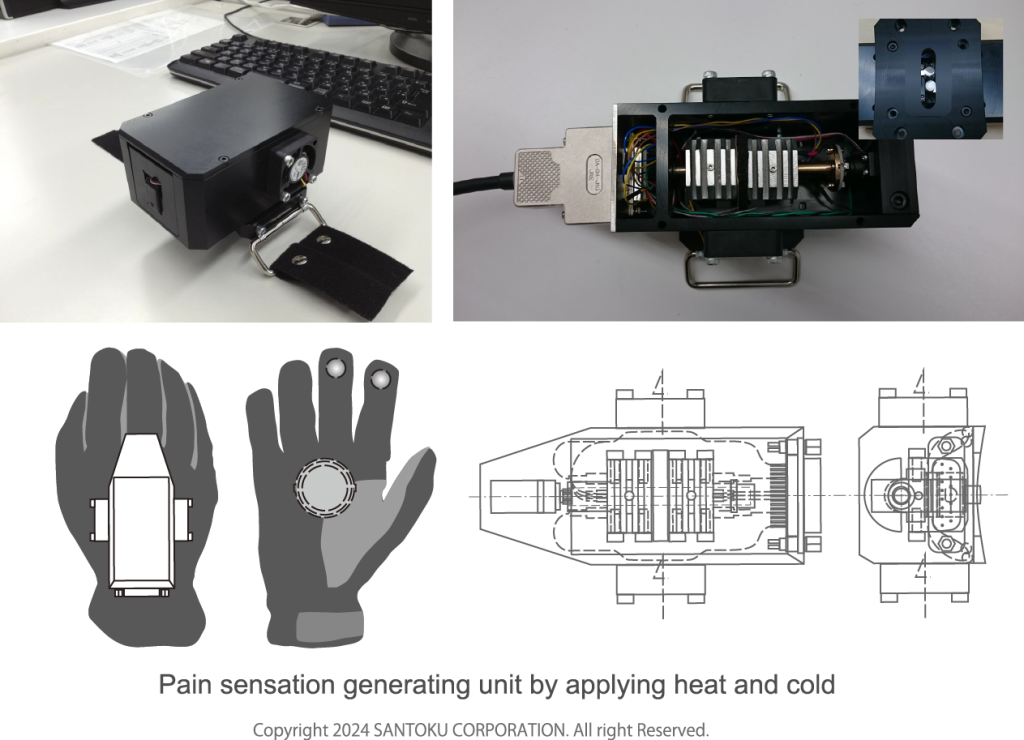

The unit shown in the figure is a prototype of a pain reproduction device using the thermal grill illusion developed in 2017. Two Peltier elements are used to create hot and cold sensations through temperature feedback control. The Peltier element controls the temperature by passing electricity through feedback control by a temperature sensor. The heat generated by the Peltier element is cooled by taking in fresh air from the outside through a heat sink and a fan, while the excess heat is released to the outside. The hot and cold zones are directly transmitted to the skin through a temperature transmission probe. The two probes are fixed on the axis of a servo motor. The motor’s continuous reverse rotational motion applies alternating hot and cold sensations to the skin. This method was able to realize a mechanism for generating the thermal grill illusion, but operational obstacles were found. One of the obstacles is the weight of the unit. Since we were considering applying hot and cold to the back of the hand, the weight has a negative impact on the physical sensation. Another obstacle is that condensation occurs on the cooling side to reproduce temperatures below 10°C. This requires measures to eliminate the effects of water droplets. In addition, the complex mechanism equipped with a motor has major concerns about durability and maintainability when considering use in the harsh environment of a manufacturing site, and we decided that it would be difficult to mass-produce it when these factors are taken into account, so we gave up on commercializing it.

Additional explanation: As it is called the thermal grill illusion, the sensation caused by the thermal grill illusion is slightly different from the pain sensation that occurs when skin tissue is destroyed. This sensation, which is caused by alternating hot and cold stimulation, is similar to the sensation of itching just before it becomes painful. The sensation reproduction in this unit does not impart a hot sensation that would accompany a burn, so please think of it as an illusion phenomenon that evokes pain. (Added on March 4, 2025)