Since 2005, we have been working with research institutes to develop video materials that recreate accidents involving children, and continue to develop disaster videos. The purpose was to inform society of the circumstances in which accidents occur and to reduce the number of accidents involving children. From 2012, we have been working with research institutes to develop a training simulator to reduce the damage caused by natural disasters. Soon after, we will develop a training simulator for the government to protect nuclear power plants from terrorism. After that, we will develop a training simulator for decommissioning work to safely close nuclear power plants. Up to this stage, we have been working in line with the government’s policy. Since 2014, we have been focusing on industrial accidents on our own, and together with a plant design company for power system equipment, we will focus on falls and electric shock accidents, which are issues in the power system, and begin working with companies to reduce disasters. We believe that it is important to address people’s inner selves in order to reduce disasters, and in 2014 we began developing an experiential VR simulator with the aim of improving people’s sensitivity to danger. By 2016, we will have established a means to realize an experiential VR disaster scenario, and will begin to consider a system to standardize disaster scenarios and share them with society. A major challenge in sharing disaster information is that there was a strong resistance in society to sharing disaster information with the public, as it was perceived as negative information. In order to share disaster information with society, we appealed to society for a system to standardize disaster information by “manipulating the information so that the people and places involved in the disaster cannot be identified.” While continuing to appeal to society for a system to provide disaster information, we have begun to build a disaster database little by little.

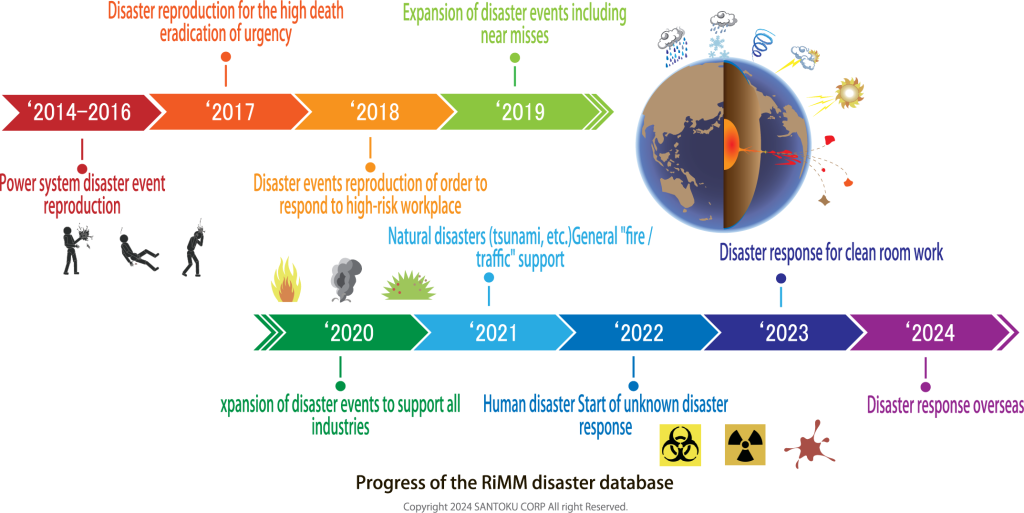

The disaster database began to be built in 2014, focusing mainly on power-related disasters. The first disaster scenario product was commercialized in the summer of 2016 and sales began. After that, we continued to build disaster scenarios focusing on six disasters (falls, electric shock, being trapped, being caught, tripping, and poisoning) that are related to highly urgent fatal accidents. From 2018, the number of safety-conscious companies that agree to standardize disaster information began to increase. From 2019, construction of disaster scenarios including near misses began. From 2020, requests to prepare information on occupational accidents that occur in 30 occupations will increase and we will begin to respond to them. In 2021, requests to develop scenarios in response to natural disasters will begin to increase. Next, companies will be required to respond to man-made disasters and will begin development. Demands for disasters occurring in society will continue to increase one after another. There is also a demand to respond to general disasters in response to traffic and fire disasters. From 2023, after the end of the coronavirus pandemic, requests to develop scenarios in response to disasters in clean room environments used in food manufacturing, pharmaceutical manufacturing, and semiconductor manufacturing will begin to increase. In addition, from 2024, overseas manufacturing companies will also be required to respond. RiMM’s disaster experience machine has been used in more than eight countries so far, and multilingual support is rapidly progressing in line with use in the ASEAN and North American regions. Recently, requests for the use of RiMM in the Middle East and Europe have also begun to increase, and we have begun to respond to them. As a result, work is underway to develop a system for sharing disaster databases socially around the world.